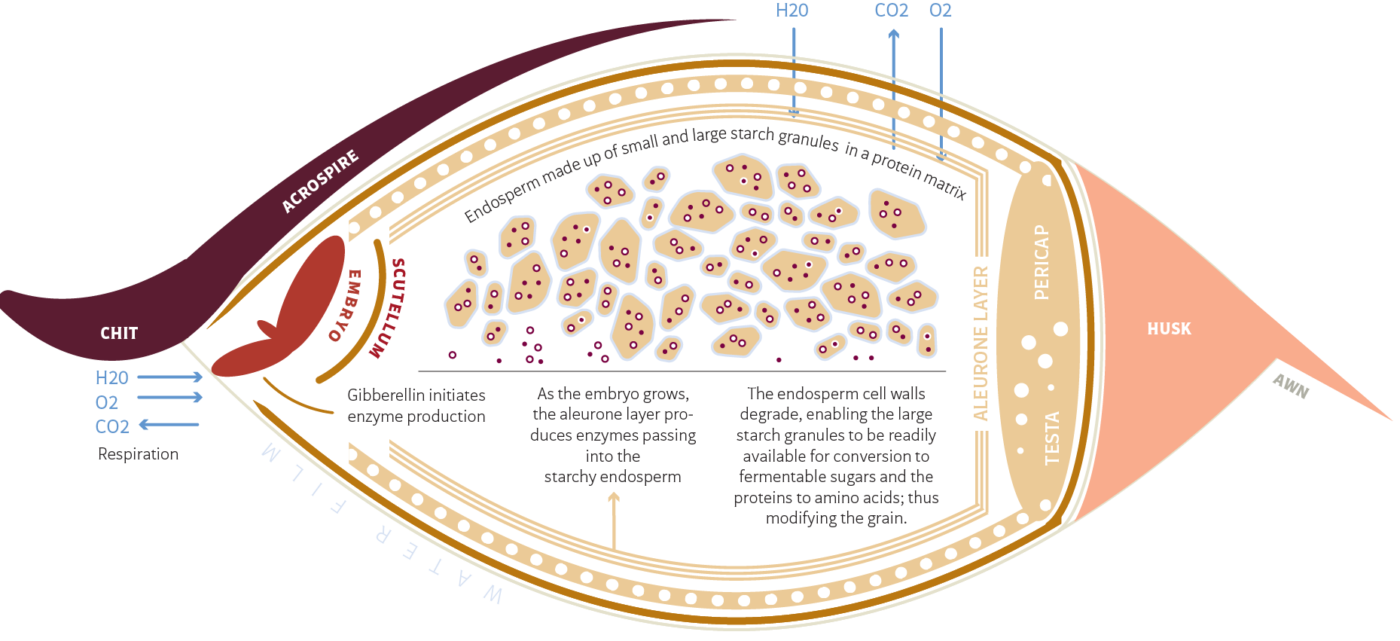

THE SCIENCE OF MALT

GERMINATION & MODIFICATION

Barley is a principal source of carbohydrates and amino acids, its energy stored as starch encased in a protein matrix in the endosperm. The malting process is initiated by steeping or immersing the cleaned barley kernels in water. The hydration will stimulate the embryo into growth and activate the enzymes needed to modify the endosperm.